|

|

CONSTRUCTION

|

| |

| |

The construction of Little

Bazeley has been a par force effort of "trial and

error" - much of what has materialized in the end

happened to do so because something else went wrong or

didn't work at all.

Here's a brief account of how it all came together in the

end.

|

| |

|

| |

|

| |

I - PLANNING THE

LAYOUT

|

| |

| Many wise railway modellers

will tell you that the most important stage of building a

layout is planning it - and they are right. In the case

of Little Bazeley, I had the huge advantage of knowing

exactly what I wanted, namely an Inglenook Sidings

shunting puzzle, and what to avoid (by way of previous

negative experience), namely designing a layout which

would not be operable on its own and require some kind of

"add-on" in order to run it as a shunting

puzzle. Whilst both

the idea of having an Inglenook shunting puzzle as well

as giving it a name which strongly hinted at a small

layout were there right from the beginning, the original

concept centered around a much larger concept - a

"modular" layout. Planning and thinking one or

two sizes above your actual possibilities is part of the

fun, but it also shows that if left unchecked this tends

to sneak in things you didn't actually want.

|

| |

|

|

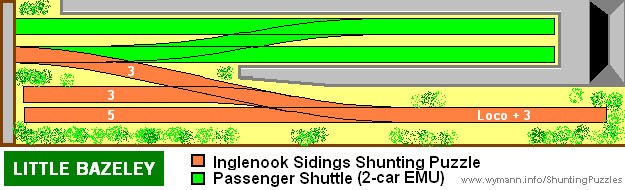

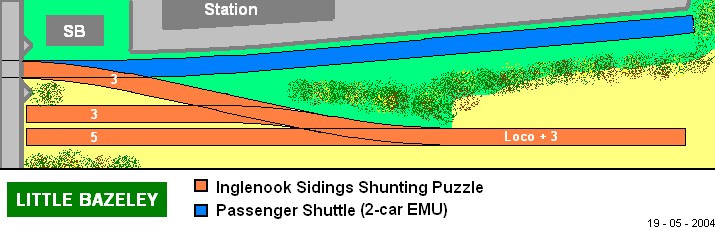

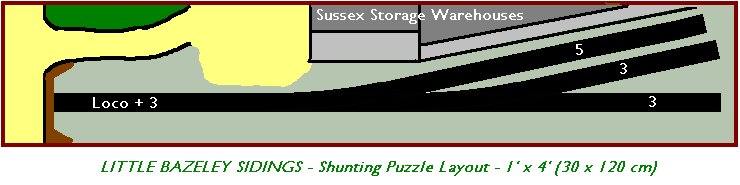

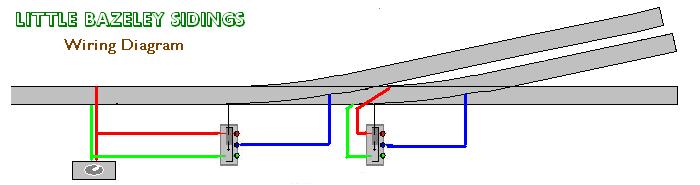

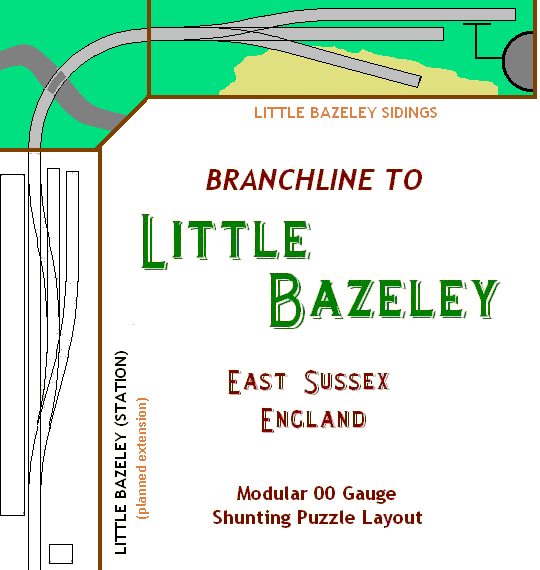

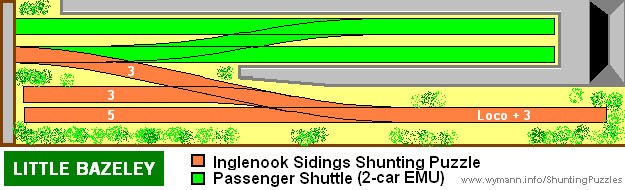

Look at

the trackplan (to the left) and you will notice

that the Inglenook Sidings "module"

would actually require a second element in order

to provide the headshunt and thus be be workable

- not good, not good at all. This was mainly due to the

fact that the initial inspiration for the layout

involved modern (and thus longer) stock: the

branchline to Lydd, which in the 1980s and 1990s

consisted entirely of nuclear flask transports

from the nearby Dungeness power station. Whilst

Little Bazeley Sidings was imagined to be

handling rather more conventional cargo, the

motive power on the Dungeenss branch in the late

1980s and 1990s begged to be replicated: the

wonderful (well, to me) class 73 Electro-Diesels.

|

|

| |

| Because I wanted the layout

not only to be self-contained but also to remain

portable, I knew (again from past - and failed -

attempts, such as Battersea

Sidings) that

4' (120cm) would be the maximum length. Even opting for a

ballast depot and using comparatively short wheelbase

"Dogfish" ballast hoppers (built in the 1950s),

there was no way this was going to fit into the

restricted layout dimensions actually possible and

available for this project. It became clearer and clearer

that in order to fit it all onto a 4'x1' (120cm x 30cm)

baseboard, the stock to be run on the layout would need

to shrink in length. This

is where coincidence (or destiny, if you prefer to look

at it that way) takes over as Bachmann was just releasing

their

model of a Class 04 diesel shunter in weathered BR green

livery and pre-TOPS numbering as D2228.

|

| |

| Built by BR as the 'standard'

small 0-6-0 diesel mechanical shunter, they were

used in areas where smaller shunting locos were

needed, such as docks or areas where traffic

flows were light. When in addition I discovered

that D2228 had spent its working life along the

South Coast, matters were settled. Without much

thinking, I had thus set the time back to the mid

to late 1960s and resolved the problem with

overlong stock nicely - as proven by temporarily putting down some

lengths of track and actually measuring up the

length of rolling stock plus the newly acquired

Cl 04 shunter. That way, I knew exactly what I

got in terms of dimensions and shunting space. |

|

|

|

| |

| Whilst this sorted out the

length of the track spurs required for the Inglenook

Sidings shunting puzzle, I initially tried to incorporate

a terminus station into the layout - a typically British

habit |

| |

| The

idea was to incorporate an EMU shuttle for added

variety, but the resulting station concourse

would have made for a fairly crowded affair -

which definitely was not the kind of location I

had in mind and which would carry a name such as

Little Bazeley. |

|

|

|

| |

| So, in a

next step, the passenger station and its facilities were

reduced drastcially in scope and size by cutting down the

double track and two platform formula to just one single

trcak with adjoining platform. |

| |

|

|

This looked and felt a lot

better and really could have passed on to the

construction stage - if not, once again, for the

fact that the EMU shuttle was a nice idea but

came with a problem: it would not be operable

without an added extension. |

|

| |

And so, I reminded myself

of C. J. Freezer's booklet 60 Plans

for Small Locations (first published in the late

1950s) and his statement concerning shunting layouts:

"it

is not obligatory to incorporate passenger facilities

into a layout, and indeed there can be very real

benefits when a small layout is designed around a

specialised service."

|

| |

| And

so - in a move to "reduce to the

max" - the plan for the layout was

revised in a way which did away with any

kind of passenger facility completely. |

|

|

|

|

| |

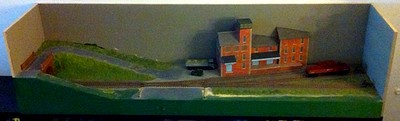

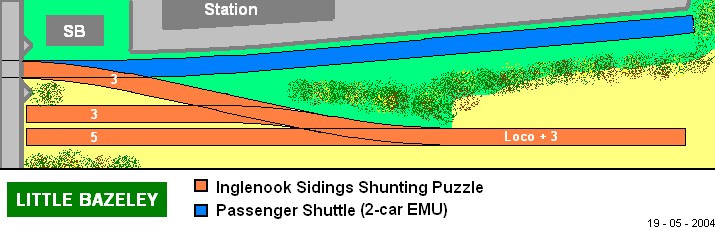

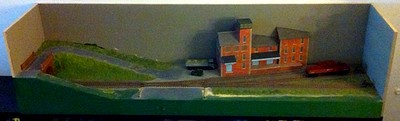

| This layout and track plan

met all the criteria I had set out to start with: it was

an Inglenook Sidings type shunting layout which was both

portable and self-contained, i.e. which could be operated

without any addition to the layout. It was now definitely time to get out

a hammer and some nails.

|

| |

|

| |

| The

start to any layout construction is the baseboard, and

here the golden rule is that nothing you put on top of it

will really keep the promises it holds unless the

baseboard you use is built to last, keeps its shape and

provides you with an even surface. Originally

intending to build Little Bazeley Sidings on a

"ready made baseboard" by using a 120x28 cm

chest with drawers from IKEA (the famous

"Moppe", used by several modellers at the

time), I found that this was being discontinued just as I

was about to start the project.

|

| |

| I therefore turned to my

previous baseboard construction methods, using

10mm birch plywood for extra strength and

rigidity whilst at the same time keeping the

overall weight fairly low. The actual baseboard

top (4'x1' / 120x30 cm - a size which is still

just about portable) is set onto a framework

structure which serves as the main structural

support for the layout. Thanks to the spacers, it

is rock solid and the best insurance against

warping. At this stage, others will

still think you're actually in the process of

accomplishing some nice practical carpentry work.

|

|

|

|

| |

|

| |

| The

track used on this layout is Peco Streamline

code 100 flextrack with medium radius electrofrog points

- my standard choice for about 20 years now. Using

Marklin Z Scale track pins sparingly, the simple track

configuration was laid down in virtually no time at all. |

| |

|

|

As all pieces of track are

straight I sprayed them a dark brown colour

(using an aerosol spray can) and then touched up

the side of the rails with a lighter rust colour

(using a fine artist's brush) before putting the

rails and points (which were not sprayed in order

to avoid conductivity problems - more about this

below) down. Weathered or not, the track is now

ready, and a shunting puzzle layout needs nothing

more than this to be operational. |

|

| |

| In

reality, however, few people can resist decorating this

bare gameboard... |

| |

Weathering

the track is an essential part of recreating the

atmosphere of the real railways. The colours vary

greatly on the prototype, ranging from dark,

almost black to to a very light rusty brown.

Eventually, it's a matter of taste as everything

else. However, applying weathering to the track

is best done with a subtle approach, as too much

colour can muck up the pointwork and reduce

electrical conductivity to critical levels - over

the past few years, I found that I was having

more and more trouble with electrofrog points

after painting and ballasting, as they no longer

did what they should have done, i.e. change the

polarity of the frog according to which way the

points were set.

|

|

|

|

| |

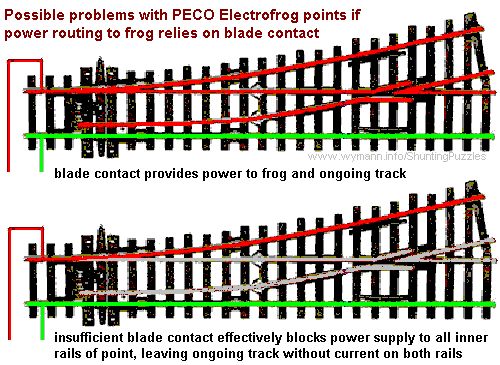

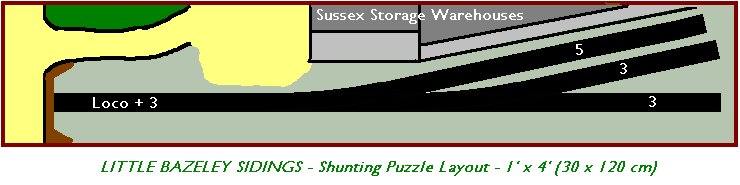

| The

problem is not unkown (straight from the box the points

rely on physical contact of the switch blade and the

outer rail, so if paint gets onto this there's no

electric contact), but it seems to have plagued my

efforts more and more in recent years. |

| |

|

|

It is such a devil of a

problem because a blade which no longer provides

effective contact with the outer rails no longer

supplies the necessary electric power to the

frog. As a result of this, the

point effectively becomes an isolating point,

with any ongoing track cut off from the necessary

electrical power supply to both rails. More often

than not, the fault can't be rectified with the

point in place. Lifting the point means lifting

the connecting pieces of track, too...

The solution to overcome this

possible problem is well-known and well-published

in the model railway press - add separate wiring

to the frog which will provide a direct means of

routing current.

|

| |

|

|

|

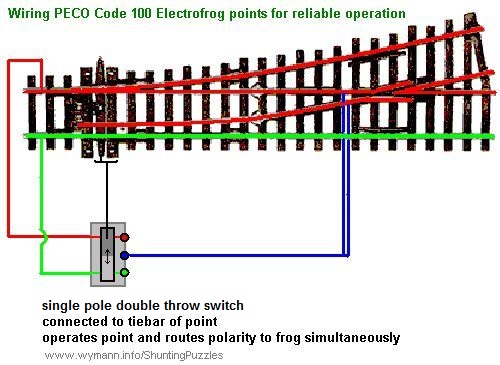

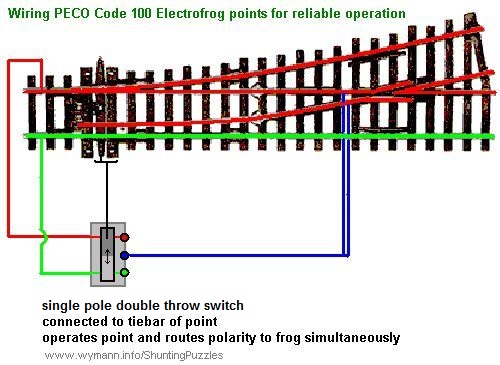

| Like it or not, eventually

the facts of railway modelling are such that

reliable pointwork simply is not guaranteed

straight out of the box (no matter which make you

choose), and it gets worse if you weather and

ballast your points. With

the otherwise well constructed Peco points,

ensuring reliable routing of polarity to the frog

is an easy and straightforward task (with the

code 75 points, it's even pre-installed to a

certain extent).

Because this wiring

arrangement requires the changing of the frog

polarity to take place simultaneously with the

route setting of the point, you either require a

point motor which is equipped to do this, or you

can stick with manual control and use a single

pole double throw (SPDT) on-on slide switch which

is connected by e.g. a rod to the tiebar of the

point.

|

|

|

|

| |

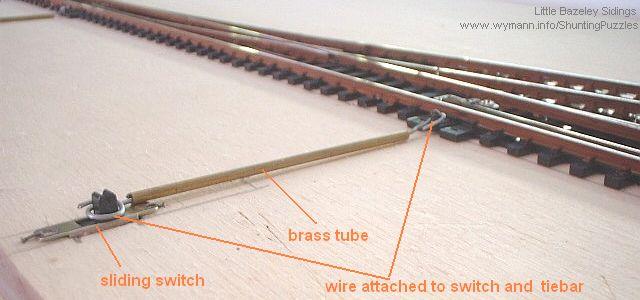

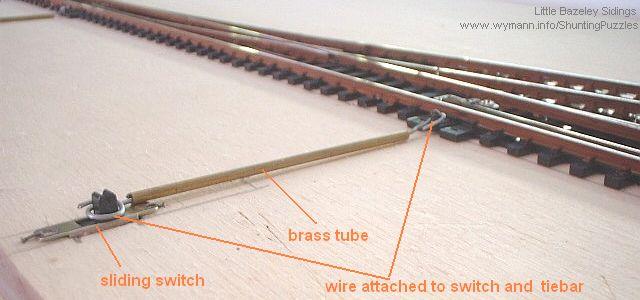

| This

way, if you slide the switch to throw the point, the

polarity routing is changed at the same time. The point

is connected to the slide switch by a piece of wire which

is attached to the tiebar and the slider of the switch. |

| |

|

|

In order to prevent unwanted

sideway movements and to strengthen the

connection, the wire is run through a brass tube

for the length of the distance between the tiebar

and the slide. It's an easy,

dependable, and cheap method of remotely

controlling the points. At a later scenery stage,

the whole thing will be disguised with foliage

and such to make it less conspicuous.

|

|

| |

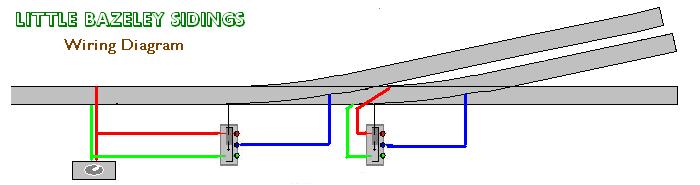

| For

the time being, Little Bazeley Sidings is wired for

analog operation (DC) despite the fact that the newer

shunters from Bachmann and Hornby are all DCC-ready. The

DC wiring on such a small and compact layout is, however,

almost as straightforward as it would be for DCC. In

fact, apart from the main feed, the only wiring in place

is for polarity switching of the point frogs, as

described above. As the points are operated manually,

there is no need for point motor wiring. |

| |

|

| |

IV - BALLASTING THE

TRACK

|

| |

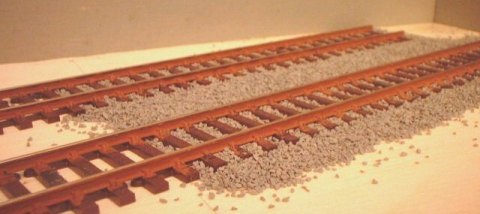

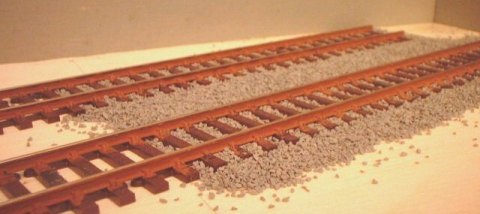

| Once

the functional aspects of the track are settled, it's

time to add ballast to the weathered track - an essential

part of recreating the atmosphere of the real railways. |

| |

Just

as with the track itself, the colours of ballast

vary greatly on the prototype, depending on the

type of stone used and how much soil and rust is

deposited on the trackbed by traffic on the line.

Personally, I prefer the look

of grey ballast - which is not restricted to

newly ballasted tracks at all. Many yards with

light shunting traffic display light coloured

ballast, simply because there's not enough

activity to deposit tons of dirt and rust, even

over the course of a few years. The weeds,

however, are a different story...

The overall effect is,

however, not only dependent on the materials used

but also on the lighting. Just how much

difference this can make can be seen from the two

views on the left: the initial stage of

ballasting (above), was photographed with the use

of artificial light, whilst the same track and

ballast at an advanced stage (below) appear to be

quite different when photographed in late

afternoon sunlight.

|

|

|

|

| |

| My

preferred make of model ballast is Woodlands Scenic

medium grey ballast, although the fine grade would

certainly be closer to scale. However, with weeds and

other green overgrowth to be added later, the appearance

to me is just fine, and it seems a lot easier to handle.

The ballast is sprinkled in place, then covered in a mist

of water and washing up liquid (also dubbed "wet

water", this brakes up the surface tension) from an

old aftershave sprayer until the ballast is quite soaked.

Immediately after this, a mixture of water and white glue

(approximately mixed at a 2:1 ratio) is carefully

dribbled onto this by employing a syringe (mine came as a

spare from the vet). The whole trackbed should be quite

white in appearance and then left to dry for a good 24

hours. After this, the ballast will be hard as concrete

(well, almost) - which is why it pays to check for

dislodged ballast (which can get onto the ties or, far

worse, cling to the sides of the rails) while everything

is still wet. |

| |

V - STRUCTURES

|

| |

| On

a small layout like Little Bazeley, different modelling

tasks start to interact very quickly, and it is a very

short cut from basic ballasting and landscaping to

setting up the first batch of planned structures. |

| |

|

|

My plans for the sidings at

Little Bazeley were to create a small and

somewhat enclosed place, but not too sleepy and

isolated, as I wanted at least some justification

for the movement of trains. This called for some

sort of facilities to be present, rather than

just a couple of overgrown and windswept tracks

in the middle of nowhere. I

felt that that a small warehouse would be ideal,

as this allows for some very general traffic

unless specified. My structure modelling

experience stems almost entirely from plastic

kits, but for Little Bazeley I opted for card -

mainly because to me it is such a typically

British material for structure modelling that I

felt it would reinforce the

"Englishness" I was aiming to capture

with this layout.

|

|

| |

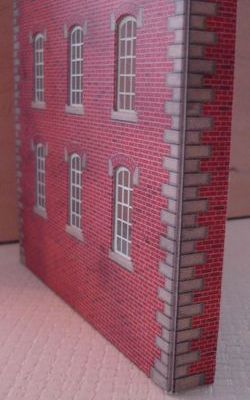

| It

would also have to be a typcially Victorian red brick

building, and I found just what I needed in the form of a

small brewery complex in the Metcalfe Models range (where

the kit carries the product code P0229), consisting of

three individual buildings. |

| |

| Obviously, certain details

which are typical for a brewery (such as roof

vents) would have to be left off in order to turn

the buildings into mere storage rather than

production facilities, but the fact that there

was precious little space behind the tracks meant

a lot of cutting and pruning anyway.

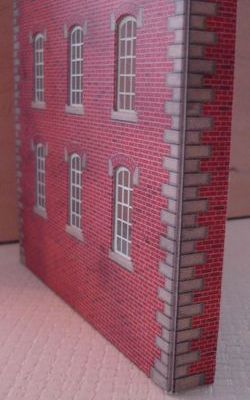

Putting card kits together is

straightforward modelling fun, and overall I

found card to be a lot easier to work with than

plastic. If you need to cut items to make them

fit a specific space, this can be done accurately

and easily - in fact, some parts of this

structure ended up being very "low

relief" indeed, as can be seen from the

building front pictured on the right.

|

|

|

|

| |

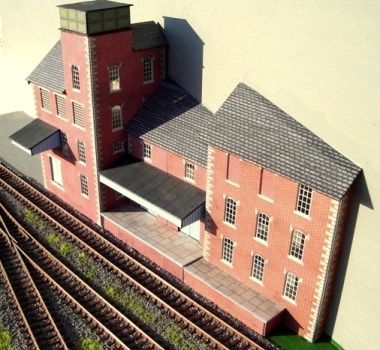

| Besides

having a charm of their own, card models these days are

pre-cut precision kits, and the brewery used on Little

Bazeley is both very sophisticated and versatile. |

| |

|

|

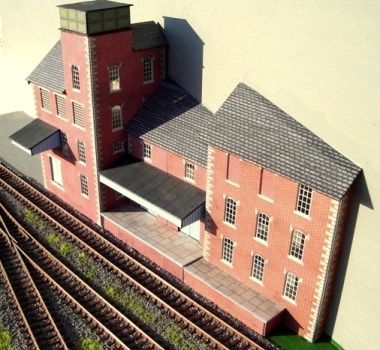

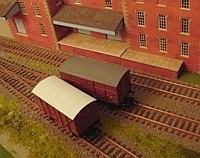

Just how much cutting and

pruning the kit had to endure can be seen from

the finished warehouse setup - the building on

the left of the structure is the only one built

(more or less) in its intended form. The

end result is quite pleasing in the sense that

even though the warehouse retains the overall

visual appearance of the brewery kit (and will no

doubt be recognised as such by a number of

modellers) it is at the same time unique in the

sense that it fits the specific location much the

same way a purpose built building would in real

life.

|

|

| |

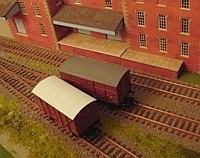

| This

type of kitbashing, however, requires extra checks on

clearances in order to ensure that all rolling stock

intended for use on the layout will clear the loading

platform edges and canopies - whilst at the same making

sure that there are no unrealistically gaping gaps

between rolling stock and (un)loading spots. |

| |

| Both the red VEA van and the

yellow 12t van are close enough to give a

convincing impression, but without fouling any

parts of the building. It is also a good idea to

make sure that clearances are compatible with the

locomotives intended for use.

It is 1966, and BR(S)

Electro-Diesel locomotive E6012 has ventured out

to Little Bazeley Sidings on a trial run.

Clearances are tight - as they would be on the

prototype - but not too tight.

|

|

|

|

| |

VI - BASIC SCENERY

|

| |

| With

the structures all in place, the right hand side of the

layout started to look fairly complete in a basic sense. |

| |

|

|

The left

hand side, however, was still a piece of

bare baseboard with un-scenicked track. The idea here was to

hide the entrance / exit of the track

(which passes through a hole in the

backdrop) by means of an overbridge from

which a road would branch off down to the

warehouse.

The bridge is an old

classic of British railway modelling.

Although the specific item used on this

layout is a 2005 production Hornby item,

it still seems to use the same mould as

employed in the 1960s by Tri-ang.

|

|

|

| |

| Picked

for sentimental reasons more than anything else, the

colouring of the plastic on this model as it comes out of

the box gives a very toy-like overall impression, but

just a simple repaint of the entire model did away with

this. |

| |

| The contours of the landscape

leading up to the bridge are modelled using a

single piece of styrofoam. It's a messy business,

but it provides a lightweight shell to work on.

This is then covered in plaster which then

receives a liberal coat of colour to seal things

up. The road surface is already

modelled into this plaster coating and only needs

appropriate colouring after this, while the rest

will receive its final touch with the sprinkling

of Woodlands Scenics scatter material.

|

|

|

|

| |

| The

realism of scenic scatter material is greatly enhanced by

mixing together two or more different colours, and the

grass used on this part of Little Bazeley is a mix of

several different types of material both in terms of

colour and texture. The final visual effect is far more

realistic than the monochrome green of just one specific

type of scatter material, |

| |

|

|

The same mix of different

shades of dark and light green scatter material

is used for grass and weeds growing onto the

tracks in front of the warehouse.

|

|

| |

| The

only thing lacking at this stage are bushes and

undergrowth, to be added on the far side of the road and

scattered along the embankment. |

| |

|

| |

| By

being "gameboards", shunting puzzle layouts

really don't require any scenicking at all - although

very few railway modellers will, of course, be able to do

completely without any scenery at all. It is, after all,

much more pleasing to the eye, and if shunting puzzle

critics point out that their operation has nothing to do

with real railways, then at least the visuals can display

some of that atmosphere. |

| |

|

|

In the case

of Little Bazeley, the basic scenery

built up initially remained just that -

basic - for all of ten years, during

which any plans to improve and add

details and finish the ballasting around

the points were postponed in favour of

operation. However, a bit of spring

cleaning highlighted the unfinished state

of things, and a decision was made to

finally add some scenic details... |

|

|

| |

| Starting at the very end of

the line, the straight siding running parallel to the

baseboard front edge was given a storage facility which,

of course, in terms of shunting puzzle operations is

completely unnecessary and "just for show". |

| |

| The

small fuel tank from Faller's range of HO plastic

injection kits (article #948) seemed just right

in terms of dimensions, and changing its

German/Continental character to something more

appropriate for Little Bazeley Sidings was easy

enough. A small project in every sense of the

word, it adds a bit of storage scenery to

complement the brick warehouse - and makes the

14t tank cars seem more at home, too. |

|

|

|

| |

| Next, the road leading up

from the warehouse to the road bridge was resurfaced to

properly resemble a tarmac road. |

| |

|

|

Too light in

colour previously, it now looks much more

like the feeder to a cross country B road

it would be if it actually ever existed.

At the same time, shades hinting at

clouds were applied to the previously

unfiorm grey backdrop, and a hedge of

bushes (consisting of a mix of Woodland Scenics

light green (FC145) and dark green

(FC147) bushes) added. They soften

the transition between scenery and

backdrop and are a first step indicating

just how much detail scenery makes basic

scenery come to life and look much more

refined even with the simplest of touches

added. |

|

|

| |

| |

| |

more

to come ...

|