|

|

| |

OPERATION

|

| |

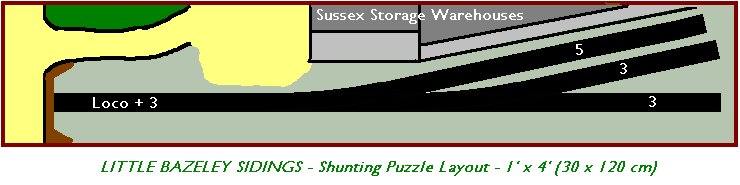

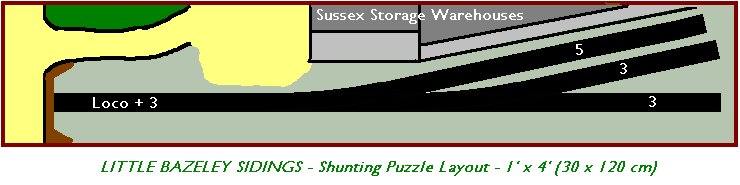

| The

layout of the sidings beyond the station at

Little Bazeley is a variation of Alan Wright's Inglenook

Sidings shunting puzzle. The choice

of a very loose 1964-1969 modelling period, being

the very last years of the British steam/diesel

transition era, just about allows for

comparatively short standard wheelbase stock of

10'-0" (3m). Scaled down to 4mm scale 00

gauge, this translates into goods wagons about

3.2" (8cm) long, i.e. short enough to allow

for the capacities needed for an Inglenook

Sidings setup within the given space of 4' x 1'

(120cm x 30cm). |

| |

|

|

| |

| The

warehouse setting is left fairly unspecific as to

who exactly receives and ships what, which allows

for a fair variety of freight stock to be used.

The shunting puzzle is fully workable within the

limits of the baseboard on the basis of the original Inglenook

rules. |

|

| |

Shunting Order

for Little Bazeley Sidings

1. Form a departing train consisting

of 5 out of the 8 wagons sitting in the sidings

2. The 5 wagons are selected at

random

3. The train must be made up of the 5

wagons in the order in which they are selected

|

| |

Couplers

|

| |

One essential aspect of

operating a shunting layout is the choice of

couplers and the uncoupling system to go with

them. Since the late 1990s manufacturers have

acknowledged the importance of reliably working

couplers by either having their products

factory-fitted with such couplers (as in the US,

where magnetic couplers in the mould of the Kadee

system are now almost standard fittings) or by

providing coupler pockets in accordance with the

NEM 362 norm, allowing modellers to substitute

the factory-fitted couplers with a different

coupler of their choice by simply plugging this

into the pocket.

|

| |

|

|

|

Ever since developed by

Tri-ang in the late 1950s, the tension lock

coupler has been the standard device used on

British 00 scale models. Consisting of a fixed

loop bar and a raisable "fish-hook",

they are foremost and above all designed to

perform automatic coupling. This is

achieved by pushing the hook through forward

motion over the loop of the next vehicule's

coupler; once the hook drops again, the two items

of rolling stock are securely coupled and, thanks

to the barbed form of the hook, interlocked - in

fact so much so that uncoupling becomes

a major problem, even when taking stock off the

rails.

|

|

| |

| In general,

tension lock couplers are therefore regarded as being

both unsightly and operations-unfriendly, and only

suffered because ready-to-run UK models offer no

alternative. |

| |

| As can be deduced by the way

a tension lock coupler works, uncoupling can only

be achieved by way of lifting the hook

sufficiently in order to allow the loop to pass

under it again - and this will only work when the

couplers are not under tension (hence their

name), i.e. the rolling stock is standing still. The

"classic" way of achieving this is by

using a sprung ramp between the rails. When a

train passes over it, the couplers are

interlocked through the tension and depress the

ramp. However, if the train stops, the ramp will

lift the now loose coupling hooks, splitting the

consist at this point.

The

problem is that this works fine most of the time

but not all of the time, and unwanted uncoupling

increases as the speed of a train passing over

the ramp decreases - as would of course be the

case on a shunting layout such as Little Bazeley.

The

answer to this problem is to have an uncoupling

ramp which is not permanently "active",

i.e. which is raised to push up the hooks only

when rolling stock standing over it is intended

to be uncoupled. A number of home-made systems,

ranging from basic to highly complex, have been

developed by numerous individuals, and there are

even commercially produced motorized solutions

which are push-button activated.

|

|

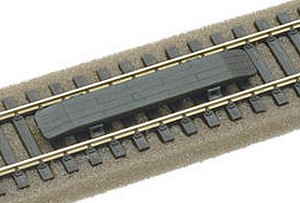

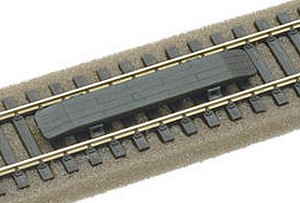

Peco uncoupling ramp (above), Gaugemaster

uncoupler (below)

|

|

| |

| This allows

for remote uncoupling, but only at the exact location of

an uncoupling device, as tension lock couplers

immediately recouple once the hook is no longer raised,

making "delayed uncoupling" (i.e. pushing an

uncoupled wagon to a point beyond the uncoupling device)

impossible without modification to the couplers. This is one of the

major features and advantages of magnetic

uncoupling systems such as used by the well-known Kadee /

MicroTrains couplers, which (together with their much

sleeker appearance) accounts for their growing popularity

with UK prototype modellers. This is further heightened

by the now de facto standard of NEM 362 coupler

pockets on 00 scale models which allow for easy swapping

of couplers equipped with a swallow-tail end.

|

| |

|

|

Unfortunately,

the NEM

362 specifications are mostly

adhered to by manufacturers with regard to the

pocket and coupler shafts but interpreted rather

loosely in terms of the distance to the railhead

(which NEM 362 sets out as 8.5mm with a tolerance

of +/- 0.2).

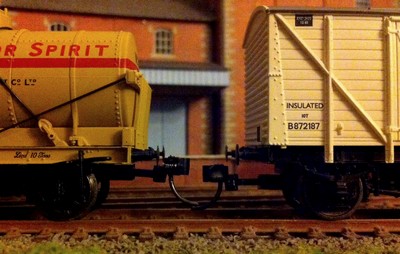

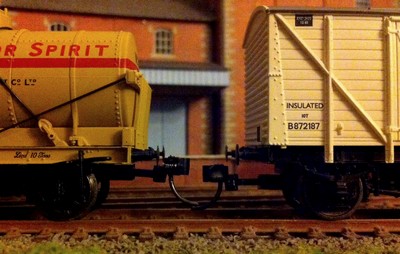

The negative effect this can

have on UK models fitted with Kadee couplers is

illustrated here: two pieces of rolling stock

from the same manufacturer (Bachmann UK) using

the very same NEM 362 Kadee couplers provide no

guarantee that the couplers will line up

correctly.

The different heights at

which the coupler pockets are located are clearly

visible in this random example.

|

|

| |

| This

results in a call for some major surgery in order to

achieve reliable uncoupling as Kadees (as well as other

magnetic buckeye couplers) tolerate little to no

misalignment in height between two couplers. But even if

all is well adjusted (and Kadee even produces a special

purpose vertical and lateral gauging tool to serve this

end), full reliability is not guaranteed. Again, uncoupling

is usually the bigger problem, leading to the strange

"Kadee dance" when a locomotive can be seen

pulling rolling stock back and forth over an uncoupling

magnet because the two couplings just won't separate.

This is why a growing number of modellers remove the trip

pins (which the magnets should force sideways) on their

Kadee couplers and prefer to uncouple them manually, thus

using the couplers only for the sake of better visual

appearance (examples are the BR Springburn Yard layout (there's a youtube video showing the pinless

Kadees during shunting moves) or the GWR/SR Hintock Branch 00

scale layout). |

| |

| One big advantage of the

Inglenook concept as operated on Little Bazeley

is that uncoupling moves only take place in one

direction (as all of the sidings point the same

way) and that the actual position of the freight

stock is of no importance as long as the maximum

number per siding is being respected and no

points are blocked. So,

it was back to the traditional tension lock

couplers for Little Bazeley as I really could not

be bothered with the major hassle of fitting and

adjusting Kadee couplers even on as few as the 8

cars necessary for the Inglenook operation (even

less so as Kadees are the most expensive option

by far) when reliable uncoupling was not assured.

|

|

|

|

| |

| Kadees

require magnets for uncoupling, and there is an

alternative to the "activated uncoupling ramp"

approach for tension lock couplers which makes use of

magnets too. First described by Brian Kirby in December

2008 on rmweb.co.uk, this

method modifies the narrow Bachmann tension lock couplers

(which feature a coupling hook made of non-magnetic

material) by adding a bent iron staple to the hook. As

the rolling stock passes over a magnet, the hook is

pushed upwards as the staple is being drawn down by the

magnet. |

| |

|

|

Putting the

concept to the test using rather coarse staple

samples (they are bent so that the inward leg

rises back against the wagon floor in

approximately a 45 degree angle) the setup worked

fairly reliably, especially when using fairly

large (i.e. thick) iron staples - finer examples

took more finetuning until they were attracted

downwards by one of the two magnets (one for each

coupler) between the track.

In comparison to any

self-made raisable uncoupling ramp (which can run

into unexpected re-alignment difficulties when

lowered back to in-between the tracks), the Kirby

method has the advantage of working faultlessly

once all the couplings are set up properly.

|

|

| |

| Just how

much time and effort one is prepared to invest in the

"setting up" of couplers and uncoupling devices

is a matter of taste and possibly also modelling skills.

Personally I found that adding the staples to the

counterarms of the coupling hooks took quite some time

and effort, yet reliable uncoupling on Little Bazeley

during extensive test runs was not assured. Whilst certainly due

to the flaws and shortcomings of the setup and not of the

method as such, I felt what I really wanted was an

uncoupling system which echoed the simplicity of the

layout itself. |

| |

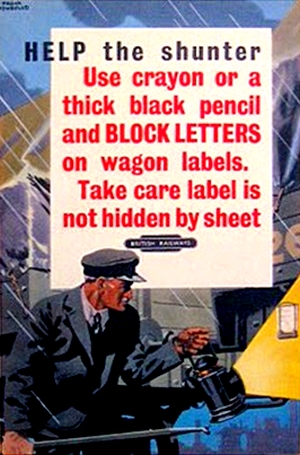

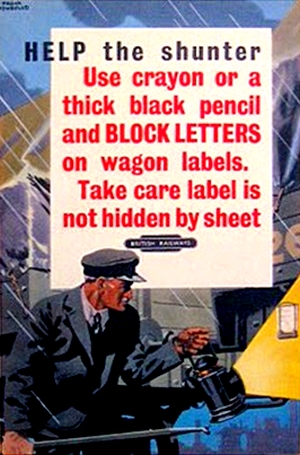

| "Simple" and

"prototypical" usually don't go

together, but in this case I found that the way

shunting was performed on British Railways in the

1960s gave me the idea on how I was going to

uncouple rolling stock on Little Bazeley Sidings. Now

of course BR didn't use tension lock couplers.

But the main tool used when

working with hook-and-chain couplings was a shunting

pole which allowed the employee (called a shunter)

to reach between wagons to fasten and unfasten

couplings without having to physically place

himself between the rolling stock (and thus

reduced the risk of accidents). The shunter shown

in a 1950s BR in-house poster can be seen

carrying such a shunting pole in his right hand.

And

this is where Sid comes in.

Sid

is, of course, short for Sidney, the regular

shunter on runs to and from Little Bazeley

Sidings. But then Sid could also be seen as an

acronym for "simple device"

- for uncoupling, that is.

In

reality, Sid is a figure from a Preiser set of

track workers (#10418) and glued to a thin wire

with a 90 degrees hook at the end which

effectively acts as a shunting pole. I got the

basic - and ultra simple - idea of the hook from

a youtube video and

then simply added Sid as a slightly

tongue-in-cheek decoration. Just like the shunter

on the BR poster, he uses his pole to uncouple

rolling stock at Little Bazeley Sidings.

|

|

|

|

| |

| Most

uncoupling systems primarily try to avoid having the

infamous "big hand from the sky" appear. But

the "look no hands" approach has some very

noticeable flaws when used with tension lock couplers. No

matter whether it's the traditional sprung ramp or a

magnetic device that does the uncoupling, rolling stock

will always be uncoupled and remain at the very same spot

(i.e. where the uncoupling device is located). This is

because delayed uncoupling (where couplers are separated

and do not recouple if the wagons are pushed forward

after the uncoupling) is rather impractical with UK

tension lock couplers (although possible using a modified

Kirby system, as shown in this youtube video). The ultra simplistic

way of uncoupling tension lock couplers which Sid brings

to Little Bazeley seemed much better suited for a

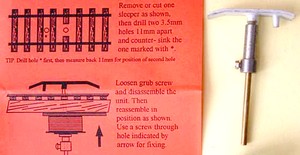

shunting puzzle. The only modification to the original

youtube idea needed to ensure reliable uncoupling was to

remove the hooks from the couplers facing away from the

bufferstops at the sidings - this way, the hook only

needs to lift one single hook and instant re-coupling is

minimized (which I found to be a frequent occurence with

both hooks in place).

|

| |

|

| |

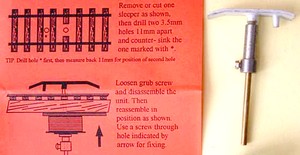

Seen here is the single hook coupling

setup (left), the paperclip wire hook inserted between

the two loop bars (centre)

and finally the uncoupling of the two goods wagons by the

simple lifting action of the wire hook (right).

|

| |

|

|

After initial tests I went

for something just a wee bit more elaborate - a

small 1.5mm Allen wrench which fits the purpose

just perfectly. Attaching Sid the shunter with

superglue really only serves cosmetic purposes... The big advantages of having

Sid do the uncoupling, basically, are:

a) no visually obtrusive

uncoupling devices,

b) only very minor modification of ready-to-run

stock required (removal of one single coupling

hook per wagon),

c) uncoupling is possible anywhere on the layout,

d) extremely cheap uncoupling system (as low as

the cost of a single paperclip if going for a

truly basic tool approach)

The major disadvantage for

many will, of course, be the big hand from the

sky involved in the uncoupling, but I have found

that ultimately this bothers me a lot less than a

hands-free magnetic uncoupling system which

doesn't work reliably.

|

|

|

|

| |

| |

|

| |

|

| |