|

OPERATING

A

SHUNTING PUZZLE LAYOUT

|

| |

|

| |

Scale

speed

- Couplers - Setting up the game

|

|

| |

| Once you have built a shunting puzzle layout with sound baseboard

foundations and track laid down in a trackplan

arrangement which allows for the rules of your chosen

shunting puzzle and provides smooth and reliable running

of your stock, you will want to operate it - after all,

you have set up the playing board, now you want to have

fun actually playing the game - for which you may find a

few useful or interesting hints here. |

| |

|

|

The

actual rules of various shunting puzzles are

covered elsewhere (e.g. here for Inglenook

Sidings and here for the Timesaver)

- this page is all about making things move on a

shunting puzzle layout.

|

|

| |

Scale

speed

|

| |

| A

shunting puzzle requires a model locomotive which runs

reliably at slow speeds. In doing so, it replicates the

prototype which doesn't allow excessive crashing and

banging simply because real railway shunting operations

try to minimize damage inflicted on rolling stock (and

the goods it carries) as well as accidents. |

| |

Class 08 (UK) - max speed 27mph

ALCO

S-1 (USA) - max speed 60mph

Ee 3/3 (Switzerland) - max

speed 25mph

|

|

Back

in the 1980s and early 1990s this was still a

problem as many good looking model locomotives

only ran reliably at speeds which were way too

fast. Since then, the quality of the motors and

gearing used even in low cost models has improved

markedly and flywheels are now a common feature.

If anything, it is the operator today who needs

to be reminded to slow down and run his shunting

puzzle moves at near to scale prototypical

speeds. Obviously speed ranges

of shunting locomotives vary according to

location and era, but shunting moves in yards and

on industrial tracks are usually very slow.

Sometimes this is reflected in the maximum speed

range of the prototype (at 27mph, the British Cl

08 shunter can't do anything else than trundle

along even at top speed, and the Swiss Ee 3/3

couldn't even quite keep up with that, rated at a

maximum speed of 25mph), but even an Alco S1

switcher would never do anything close to its

potential 60mph when actually performing

switching duties. "On the job",

locomotives sorting out and dropping off freight

stock (or even passenger stock) will usually be

working at speeds of 5-10mph.

The best way to track the speed of your

models is to measure a straight and level stretch

of track and then note the time the locomotive

takes to cover it. In 00/H0, a model travelling

at a scale speed of 5mph (7,5 km/h) will take 12

seconds to cover a distance of 1 foot (30 cm). If

you're travelling along at 15mph (23 km/h), it's

still 4 seconds. In N scale, a model travels 0,55

inches (1,3 cm) per second at a scale speed of

5mph (7,5 km/h).

Scale speeds usually don't come for

free, they require good equipment (both

locomotives and track) which is well maintained.

As far as track is concerned, good electrical

conductivity is a must - if it can be achieved by

regular cleaning, that's fine, if not, all

electrical contacts need to be improved and maybe

additional track feeds will be necessary - and

maybe upgrading to a better control unit will be

inevitable at some point.

If a locomotive still refuses to run

slowly even under near perfect track and power

input conditions, it will simply not qulaify as

shunting puzzle motive power. Re-motoring or

re-gearing used to be the playing field of

experienced modellers prior to the 1990s, but

today that hardly seems viable - model shunters

are mostly geared to prevent extreme non-scale

speeds and come with flywheels to ensure smooth

running even when the locomotive is crawling.

|

|

| |

| |

Couplers

|

| |

| As the word coupler

implies, its primary function is to join up individual

pieces of rolling stock and ensure that they stay

coupled, be it whilst in motion or standing still. This

effectively results in the necessary control to form and

run a train without unwanted "runaway"

incidents. The same holds

true for the model - couplers are designed to attach one

piece of rolling stock to another as securely as

possible. One specific aspect of shunting puzzle layouts,

however, is the fact that uncoupling is just as

important as coupling.

|

| |

Buffer and chain coupling

(Chris McKenna)

Knuckle

coupler

(Roy Smith)

|

|

The variety

in coupler types found on railway models is, in

fact, mirrored by the prototype, where several

completely different coupling systems existed and

still exist today. In Europe, the standard device

is the buffer and chain coupling, first

used by the pioneering Liverpool and Manchester

Railway in 1830. Rolling stock is coupled by hand

using what in British railway terminology is

called a screw coupling, consisting of a hook

and chain links which are secured through an

integrated turnbuckle that draws the vehicles

together.

This

coupling requires and has brought about the

typical European feature of buffers on the ends

of rolling stock an essentially provides an

arrangement which limits the slack in trains and,

with sprung buffers, absorbs shock impact.

In North America,

today's standard AAR (Association of American

Railroads) knuckle coupler essentially

goes back to Eli H. Janney who secured a patent

for his newly designed coupling device in 1873.

Thus also called a Janney coupler (or,

in the UK, where this type of coupling is used on

certain multiple units, a buckeye coupler),

it is a semi-automatic coupler which - like the

buffer and chain coupling - needs to be unlocked

manually by using a cut lever but which

- unlike the standard European coupling - couples

and locks automatically as the knuckles of two

couplers are pushed together.

This

type of coupler is also used in a number of South

American, Asian (noteably Japan and China) and

African countries as well as in Australia and New

Zealand.

The

conclusion to be drawn from the prototype is that

there is automatic coupling, but (with very few

exceptions requiring special installations) no

automatic uncoupling. The same, incidentally,

goes for model couplings.

|

|

| |

| Ever since model

trains were produced commercially the major concern with

regard to couplings was to make sure that individual

vehicules remained coupled. This certainly makes

sense from the continuous run perspective, and therefore

the vast majority of model coupling systems supplied with

ready-to-run models for a very long time seemed to assume

that once you had coupled two items of rolling stock

together you would not want them to part again. |

| |

Standard

UK tension lock coupler

|

|

No

matter whether you're looking at the (still

current) tension lock coupler (00 scale,

UK), the (now obsolete) hook and horn coupler

(HO scale, US) , the (still predominant) drop

loop coupler (HO scale, Europe), the

(standard in Europe, fading in the US) Arnold Rapido

coupler (N scale) or the (standard for

Europe) Marklin horn coupler (Z scale) -

they all have one thing in common: None of them is designed to be uncoupled

without either the famous "big hand from the

sky" or some rather unsightly uncoupling

devices which take the form of oversize ramps in

the best of cases.

The problem

from a shunting puzzle perspective is obvious:

the fun to be gained from operation is in direct

proportion to the amount of both

coupling and uncoupling involved, and if

this is a tedious process in itself, then the fun

factor immediately drops radically.

|

|

| |

| In

order to prevent this, there is the option on a DCC

controlled layout of having rolling stock equipped with

digitally controllable couplers - if these are available

or can be retro-fitted, there are no uncoupling devices

to be installed, and yet stock can be uncoupled anywhere

on the layout. On a conventional DC layout,

(electro-)magnetic uncoupling devices have proven their

worth in terms of appearance and function over a long

period of time. |

| |

| The

pioneer maker of magnetic uncoupling devices -

Kadee (R) - was specifically

founded in 1947 by twin brothers Dale and Keith

Edwards with the intention of producing a coupler

for railroad models which looked as much as the

real thing as possible and allowed for automatic

coupling and hands-off uncoupling. Today, a fair number of producers have

their own version on offer, and the principle

underlying the operation of

"magnematic" couplers (as the famous

Kadee branding goes) is well known.

Fashioned on the knuckle coupler, the

pin running down towards the track (and thus

obviously specific to the model coupling) will be

forced sideways when running over a magnet. If

there is no pulling force on the coupling, i.e.

if the rolling stock is standing still, the

knuckle will swing sideways with the pin and open

- effectively uncoupling itself.

|

|

|

|

| |

| As the pin is still

forced outward by the magnet, pushing back into the

(open) knuckle allows for delayed uncoupling: a

piece of rolling stock can be moved to any point and

dropped off after it is uncoupled without recoupling as

long as the loco is pushing it. |

| |

|

|

Today,

most HO, N and Z scale US prototype

models are sold with Kadee/Micro-Trains

couplers or variations thereof, some of

which were born out of necessity because

Kadee/Micro-Trains would not license

their couplers to some manufacturers.

Whilst they all look pretty much the same

at first sight - as knuckle couplers

would - some do not allow for

magnetically induced uncoupling. Rokuhan,

Japanese producer of Z scale track and

models has published a video on youtube advertising their

uncoupling track which nicely shows how

"magnematic" uncoupling works,

illustrating as a side-effect how well

suited this type of coupling/uncoupling

is for a shunting puzzle layout.

However, using Kadee

couplers with European or British outline

stock is not as straightforward as the

existence of the NEM-362 coupler pocket

would suggest, even though Kadee has a

range of different couplers suitable for

specific models. Converting these models

to this type of couplers can still be a

task requiring skill and time.

|

|

|

| |

| Just as

important as the couplers are, of course, the

uncoupling devices. They, like the couplings,

should work reliably. Most layouts running stock

which is equipped with "magnematic"

couplers use uncoupling magnets which are either

installed between (i.e. visible) or under the

running rails (i.e. out of sight). The

magnets don't look all too prototypical, of

course, but there are a number of ways to make

them less conspicuous (e.g. using them as part of

a yard pathway crossing the tracks). The magnets

which are installed below the track usually

produce a stronger magnetic field; apart from the

fact that they require a lot of advance planing

(they can't be installed once the track is fixed

down and ballasted) they also have a strong

tendency to interfere with the running of trains,

causing unwanted side-effects such as metal axles

and loco metal underframes being "locked

on".

Some

manufacturers offer set pieces of

"uncoupling tracks" which have a magnet

ready installed between the rails (e.g. Kato

Unitrack) or out of sight (e.g. Rokuhan Z scale

track which hides the magnet in the preformed

roadbed).

|

|

A Micro-Trains N scale

uncoupling magnet in place on an Inglenook

Sidings layout

|

|

| |

| The

positioning of uncoupling devices is also very crucial

for a successful shunting puzzle layout - there should at

least be enough of them to allow for all the necessary

uncoupling moves. |

| |

If

necessary or desired, an Inglenook Sidings layout can be

operated with one uncoupling device only.

It would, however, be more advisable to use three

uncoupling devices (one each at the throat of each

siding) if possible.

A Timesaver layout

requires four uncoupling devices located in specific

positions.

It won't work with less, and it doesn't need more if

couplings are used which allow for delayed uncoupling.

|

| |

| Some may want to reduce the

number of uncoupling devices to a bare minimum and will

accept having to sometimes make lengthy and not very

prototypical shunting moves such as pulling the entire

string of rolling stock from its siding in order to get

at one single freight car, while others may want to

spread a larger than needed number of uncoupling devices

around the tracks. In any case, the trackplan and

operating rules of a shunting puzzle need to be studied

carefully in order to know what the minimum requirements

for uncoupling devices are. The rest is, as so often, a

matter of personal taste. Personal taste also relates to as to

whether or not to use magnetic uncoupling. Some modellers

- and there seems to have been something of a revival of

late - seem to prefer manual uncoupling. Their argument

is that this has the advantage of being able to uncouple

wherever you need or want to without any restrictions,

rather than having to pass over a magnet first. Manual

uncoupling - often using some device which can best be

described as a "stick" (for N scale, a

toothpick will indeed do the job) - also eliminates

problems with unreliable uncoupling and the necessity to

fine tune couplers. In the end, the important thing is

that uncoupling is easy and reliable - possibly the most

important point of all when operating a shunting puzzle

layout.

|

| |

| |

Setting

up the game

|

| |

| Finally, when all is

well on the layout and running smoothly, it's time to

start playing the game. With other games, this would mean

perhaps throwing a dice or picking a card - but how do

you start a game on a shunting puzzle layout? With

both classics, Inglenook Sidings and Timesaver, you need

to know which freight car (8 of them in a standard game

of Inglenook, 5 in John Allen's original way of switching

the Timesaver) is required to go where before you can

start. Obviously, there are almost endless ways of doing

this, ranging from old tech to high-tech, but it will

always involve handling tokens which represent the

individual cars and where they are to be moved.

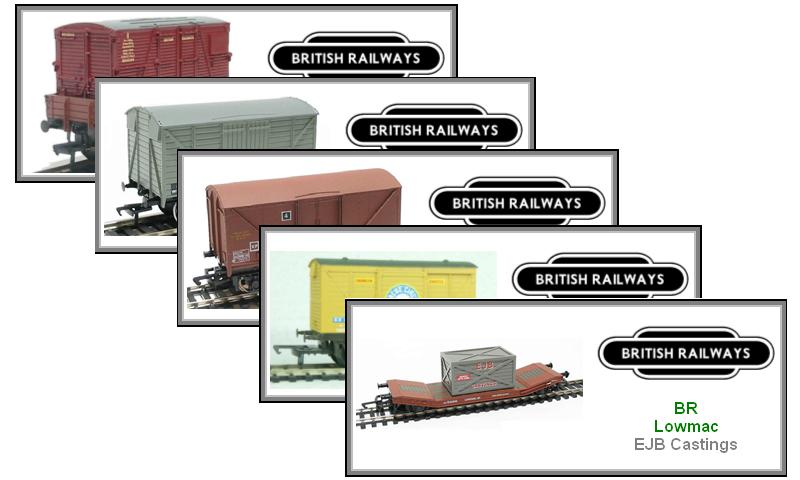

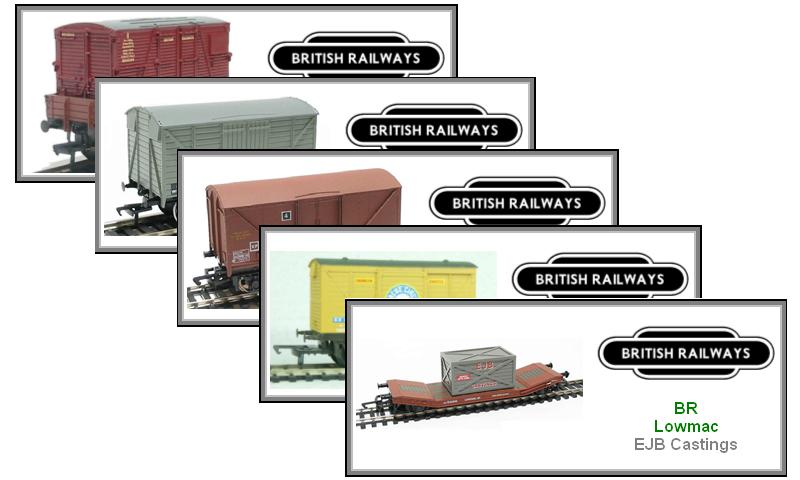

One

good idea to start with is to have distinctive looking

items of rolling stock which are easily distinguishable

(unless the shunting puzzle replicates a prototype that

used only one type of rolling stock, of course).

As

for the selection process of which piece of rolling stock

needs to go where - Alan Wright used his famous

"tiddlywink computer" (a mug which held a

tiddlywink (i.e. a token) for every piece of freight

stock on the layout) from which the required number of 5

would be drawn, and the order in which this happened at

the same time determined the order in which the cars were

required to end up. You really don't need more than that,

but I have found that using a system heavily influenced

by the classic American way of creating switching orders,

the card and waybill system, will make things unmistakeably

clear even to someone having their first go ever. The

following illustrations apply for an Inglenook Sidings

layout, but they're just as valid for a Timesaver layout

(which due to its US roots will probably feature car

cards anyway).

The

system is quite simple. On a classic Inglenook Sidings

you have 8 freight cars, each of which needs its own card

as a means of referring to this specific car. This can be

as simple or as elaborate as you care to make it -

perhaps a slightly more elaborate form could look

something like this:

For

this US prototype Inglenook Sidings layout, every car not

only has its own card but cars have also been selected so

that the colour of the car (there's only one yellow, one

green, etc.) allows for immediate spotting of the car.

All in all, there's a total of 8 cards of identical size

which are shuffled and then the five uppermost are put

down. The order in which this takes place also serves to

determine the order in which the cars should end up.

Here,

another two cards need to be drawn, but so far you can

tell that the car which is required to be the closest to

the switcher is the the brown D&H boxcar, then the

yellow ACY boxcar, followed by the green Vermont Railway

boxcar.

It takes a bit of work to make all the cards

you'll need (though it can be done in 5 minutes if you

don't feel like having any fancy special effects), but

it's worth it, and it adds quite a bit of atmosphere to

operating a shunting puzzle layout. Naturally, the same

can be done e.g. for a UK prototype layout.

|

| |

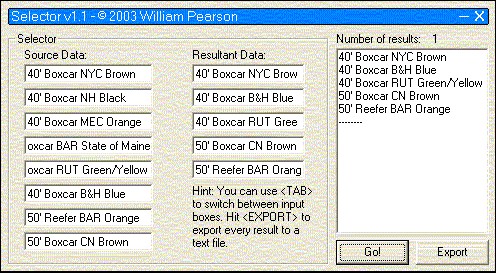

| Naturally, you could also have a computer

do the shuffling for you - which is precisely what the Inglenook

Random Wagon Selector by William Pearson will do. |

| |

|

|

This

neat little piece of software dates from 2003 (it

will still run fine on most hardware running

Windows OS), and the screenshot shows an example

list of cars on the layout and how the Selector

produces a random list of cars in the order in

which they are to be shunted (courteousy of and

with the kind permission of Mark Kendrick, you

can still download it from this site as a

zip-file). Or, if you prefer, you can input your

rolling stock into an online random list

generator and have your shunting order made up in

your web browser by simply ignoring the last

three items in the list (one example is the List Randomizer from random.org).

|

|

| |

| |

| |

|

|

| |

Text,

pictures and illustrations not labelled otherwise are © Adrian Wymann

Page created: 11/OCT/2002

Last revised: 02/JUNE/2023

|